Directed assembly of colloidal nanoparticles on surfaces

The Nanotech team develops multiple complementary approaches for the directed assembly of colloidal nanoparticles onto rigid or flexible surfaces.

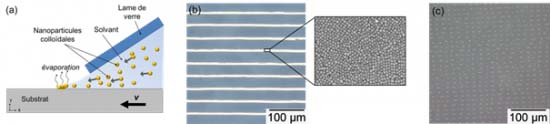

* Convective Self Assembly

The convective self assembly (CSA) technique makes use of the hydrodynamic and capillary forces that appear at the triple liquid/solid/gas line during the motion of the meniscus of a evaporating colloidal drop. It allows assembling nanoparticles and organizing them at the surface without the need of structuring it. Figure 1 shows two examples.

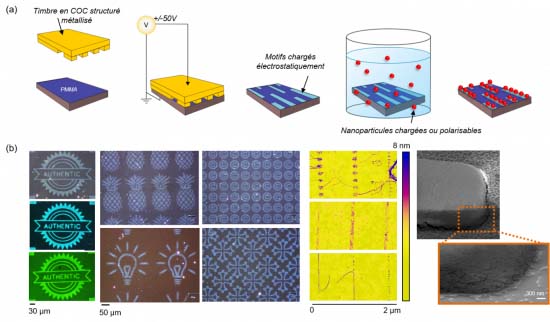

* AFM nanoxerography

AFM Nanoxerography is a technique in which charge patterns written via a polarized AFM tip on electret thin films acts as electrostatic traps to selectively assemble colloidal nanoparticles (cf. figure 2 in the case of hydrogel nanoparticles). It is a transfer at the nanoscale of the xerography process used in laser printer.

* e-µPC nanoxerography

Owing to the electrical microcontact printing technique (e-µCP), derived from the microcontact printing one, it is possible to realize in a parallel way and in a single step several thousands of charged patterns via a conductive structured stamp. The development of two automatized specific equipments, in collaboration with the companies Innopsys and NILT along with the research work on a new generation of COC stamps, allows new industrial perspectives for nanoxerography.

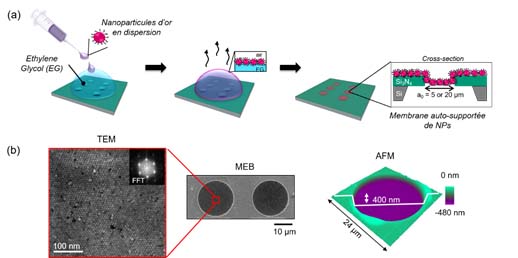

* Freestanding assembly

By depositing a drop of colloids dispersed in toluene onto a drop of Ethylege Glycol, all over opened Si3N4 membranes, the Nanotech team has demonstrated that convective assembly at ambiant temperature is possible in order to obtain gold nanoparticle monolayers, dense and organized in a hexagonal arrangement at large scale at the surface of ethylene glycol. They can then be transferred by simple heating at the surface of opened Si3N4 membranes (Figure 2). 2D membranes of freestanding nanoparticle assemblies above 20 µm wide openings are thus simply obtained, allowing to get rid of any influence of the substrate below (Figure 2).